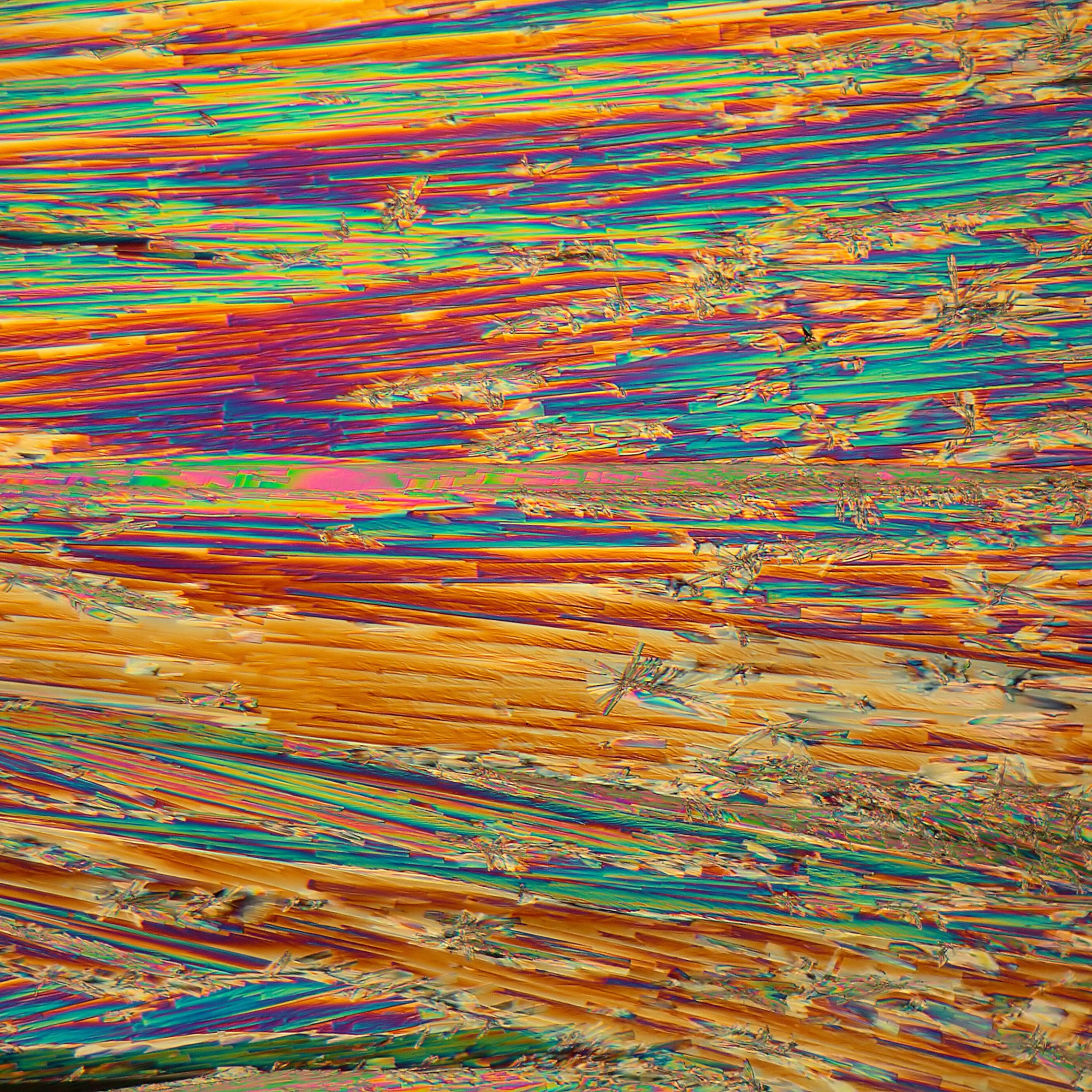

This rare earth metal shows us the future of our planet’s resources

Leaving aside meteorites that strike Earth’s surface and spacecraft that get flung out of its orbit, the quantity of materials available on this planet isn’t really changing all that much.

That simple fact of our finite resources becomes clearer and more daunting as the pace of technological change advances and our society requires an ever wider array of material inputs to sustain it. So for nearly as long as we’ve systematically extracted these substances, we’ve been trying to predict how long they will be able to meet our demand. How much can we pump from a well, or wrest from a mine, before we need to reconsider what we’re building and how?

Those predictions have grown increasingly complicated. And now it’s also a matter of how much we can pull from manufactured and discarded objects. Can we recycle parts of that iPhone, or the guts of that massive wind turbine? How much of any given object can we recirculate into our churning technological economy?

Estimates of how much material we’ll have access to in the future tend to have a tricky, often implicit assumption at their center: that we’ll be making roughly the same products with the same materials as today. But technology moves quickly, and by the time we understand what we might need next, or develop a specialized system to mine or recycle it, the next generation of tech might render all our assumptions obsolete.

We’re in the middle of a potentially transformative moment. The materials we need to power our world are beginning to shift from fossil fuels to energy sources that don’t produce the greenhouse-gas emissions changing our climate. Metals discovered barely more than a century ago now underpin the technologies we’re relying on for cleaner energy, and not having enough of them could slow progress.

Take neodymium, one of the rare earth metals. While far from a household name, it’s a metal that humans have relied on for generations. Since the early 20th century, neodymium has been used to give decorative glass a purplish hue. Today, it’s used in cryogenic coolers to reach ultra-low temperatures needed for devices like superconductors and in high-powered magnets that power everything from smartphones to wind turbines.

Demand for neodymium-based magnets could outstrip supply in the coming decade. The longer-term prospects for the metal’s supply aren’t as dire, but a careful look at neodymium’s potential future reveals many of the challenges we’ll likely face across the supply chain for materials in the coming century and beyond.

Peak panic

Before we get into our material future, it’s important to point out just how hard it’s always been to make accurate predictions of this kind. Just look at our continuous theorizing about the supply of fossil fuels.

One version of the story, told frequently in economics classes, goes something like this: Given that there’s a limited supply of oil, at some point the world will run out of it. Before then, we should reach some maximum amount of oil extraction, and then production will start an irreversible decline. That high point is known as “peak oil.”

This idea has been traced back as far as the early 1900s, but one of the most famous analyses came from M. King Hubbert, who was a geologist at Shell. In a 1956 paper, Hubbert considered the total amount of oil (and other fossil fuels, like coal and natural gas) that geologists had identified on the planet. From the estimated supply and the amount the world had burned through, he predicted that oil production in the US would peak and begin declining between 1965 and 1970. The peak of world oil production, he predicted, would come a bit later, in 2000.

For a while, it looked as if Hubbert was right. US oil production increased until 1970, when it reached a dramatic peak. It then declined for decades afterward, until about 2010. But then advances in drilling and fracking techniques unlocked hard-to-reach reserves. Oil production skyrocketed in the US through the 2010s, and as of 2023, the country was producing more oil than ever before.

Peak-oil panic has long outlived Hubbert, but every time economists and geologists have predicted that we’ve reached, or are about to reach, the peak of oil production, they’ve missed the mark (so far).

Now there’s a new reason we might see fossil-fuel production actually peak and eventually fall off: the energy transition. That’s shorthand for the grand effort to shift away from energy sources that produce greenhouse gases and toward renewables and other low-carbon options.

Hubbert’s theory suggested that a fixed supply would force production to decline from a peak. But as the world wakes up to the dangers of climate change, and as low-carbon energy sources like wind, solar, and nuclear take off, we may wind up leaving some coal, oil, and natural gas in the ground. Simply put, production might head back down because of a lack of demand, not a lack of supply.

Those newly ascendant energy sources, though, are ironically a new source of “peak” panic. Solar panels, wind turbines, and batteries may not require fuel, but they do require a host of metals, including lithium, copper, steel, and rare earths like neodymium.

If we extract, process, use, and discard these metals, conceptually there must be some point in the future when we run out of them. And as the energy transition has gotten underway, plenty of forecasts have attempted to understand which metals we should worry about and when they might start to be depleted. But experts say that understanding the availability of resources in this sector is much more complicated than picking out a single future peak.

“The peak modeling thing is something that doesn’t really apply to metals,” says Simon Jowitt, director of the Center for Research in Economic Geology at the University of Nevada, Reno. It’s nearly impossible to understand whether we’ve reached a peak in production for any given material, or even whether those peaks can be predicted, as Jowitt said in a 2020 paper.

Let’s take a closer look at neodymium. Reserves of the metal—the amount we know about that’s economically feasible to extract—have been estimated at 12.8 million tons. To keep the world from warming more than 1.5 °C over preindustrial levels, we might need as much as 121,000 tons every year just for wind turbines, according to a 2023 study on the material demands of the energy transition. Depending on how much material we assume makes it from the mine into final products, we could burn through those reserves in roughly a century.

If we extract, process, use, and discard these metals, conceptually there must be some point in the future when we run out of them.

The problem with this thinking, though, is that reserves and resources are far from fixed. Geologists discover new deposits all the time, for one thing. And what was considered too expensive and difficult to mine a few decades ago might be possible to extract with today’s technology. So instead of being slowly depleted, those material supplies have roughly kept up with production.

“We are currently producing more metals than ever before and have more metal resources and reserves than ever before,” as Jowitt put it in his paper.

And the question, he says, isn’t whether we’ll blow through what’s theoretically available on the planet, or even whether we’ll soon run out of material we can access and mine. It’s whether we’re willing to accept the social, ecological, and geopolitical consequences of how we mine today, and whether we might be able to change those for the better. Because we may be mining a lot more of some materials in the near future.

Big digs

Demand for rare earths is expected to explode in the coming decades, driven largely by the increased need for neodymium-based magnets. These magnets, commonly made from a mixture of neodymium, iron, and boron with other elements sprinkled in, produce a stronger magnetic field with less material than other magnets available today.

While demand for neo magnets will likely triple in the coming decade, global production of neodymium will only double, according to Adamas Intelligence, a consulting firm specializing in strategic metals and minerals. It can take close to a decade to build new mines, and those long lead times could contribute to a supply crunch, says Seaver Wang, climate co-director at the Breakthrough Institute, an environmental think tank.

Short periods when demand outstrips supply can lead to volatility, high prices, and slower deployment of new technologies. In a time as fast-moving as our current energy transition, those challenging economic conditions could have far-reaching effects, potentially entrenching old technologies and stalling progress.

But despite these expected challenges and the resulting potential for volatility, there is, in theory, plenty of neodymium to go around. Despite their name, most rare earth metals aren’t terribly rare. Many are about as abundant in Earth’s crust as copper, and neodymium is roughly 1,000 times more common in the crust than platinum or gold.

However, unlike those metals, rare earths aren’t often found in concentrated deposits. Getting one ton of metal concentrate can require moving a thousand tons of rocks.

This mining and refining process can be technically complicated and environmentally damaging, in part because rare earth metals are chemically similar to each other and difficult to separate without using harsh chemicals, says Julie Klinger, an associate professor at the University of Delaware who studies the global market for these materials.

Extraction often relies on dissolving crushed-up ore in strong acid. Mines that don’t carefully contain the waste material and the used chemicals risk polluting local waterways. Rare earth mines also often need to handle radioactive waste, since elements like thorium and uranium are common in and around the minerals that are mined to extract rare earths.

There are efforts underway to mine without producing dangerous waste, and new sites are attempting to squeeze as much finished product out of their initial mined material as possible, reintroducing scraps back into the refining process so less ends up in the waste. Others are taking another look at waste from previous mining efforts.

But some experts hope to entirely rethink material supply. Instead of extracting new materials, what if we look to what’s already been dug out of the ground?

Around and around

Follow the path of many commonly used metals, and you’ll likely trace a straight line that leads from the mine to a product and, eventually, to some version of a trash can. In an effort to ease supply concerns and environmental damage, some experts are calling for a new way of using materials, one that focuses on reducing waste or eliminating it altogether.

Such a system would bend the line that goes from mine to trash into a new shape, so extracted materials are in use for as long as possible—maybe even forever. A whole host of strategies can extend the lifetime of materials, from repairing and refurbishing products to disassembling them and recycling the metals in them once the products are beyond repair.

This can start well before products even get to consumers, by making the most of materials as they’re taken out of the ground. Where recycling really gets difficult is the point at which the materials have left a company and gone into devices, says Ikenna Nlebedim, a research scientist at Ames National Laboratory.

Follow the path of many commonly used metals, and you’ll likely trace a straight line that leads from the mine to a product and, eventually, to some version of a trash can.

Today, a small but difficult-to-quantify fraction of rare earth elements are recycled from products that have reached the end of their useful life. (Many in the industry put the figure at roughly 1%, though there’s little data available on rare earth collection, Nlebedim says.) With the looming increase in expected demand, several companies, including Noveon, REEcycle, and Cyclic Materials, are working to increase that amount, setting up the beginning of a recycling industry.

A major challenge for rising magnet recyclers is that magnets tend to make up a tiny fraction of a product’s total weight. Picking through heaps of products to recover them is an imperfect system, and magnet recyclers are left with other valuable materials that they have no interest in—and no effective process for isolating.

In the future, economical recycling of rare earths might require a broader infrastructure for recycling the rest of a device, Nlebedim says. A centralized dismantling system would allow the recovery of materials like copper, gold, and platinum group metals that are often found in the same products as rare earths. This setup would allow more of the material in waste products to be reused than is possible now, when a company will go after the highest-value, easiest-to-extract materials and toss the rest into a shredder.

Casting a wider net to recover more materials could help create a more stable supply for metals. That could be a major help if the materials considered valuable in the future are different from the ones with the most value today.

Quick shifts

Technology moves quickly, and many of the materials that are critical to us today weren’t even in use a century ago.

Just look at the history of Mountain Pass Mine, a rare earth mine in California. The mine’s critical product has changed every 20 years or so since production started in 1952, says Michael Rosenthal, cofounder and chief operating officer of MP Materials, the site’s owner.

In the 1960s, Mountain Pass produced the europium used in color television screens of the time. In the following decades the target was cerium, which was useful for the glass used in televisions with cathode ray tubes. Since CRTs have been replaced with new technology like LED screens, demand for cerium has decreased. Now the mine focuses on neodymium and praseodymium, another ingredient sometimes used in magnets.

Yet even as geologists are scouting new mines and companies are springing up to start building recycling systems, researchers are working to make rare earth magnets less central to our technological future, or maybe even obsolete.

Today, neodymium is necessary in these powerful magnets to wrangle the electrons in iron so that they spin consistently in the same direction, producing a strong magnetic field. There aren’t any alternatives that can match their performance.

However, there could be options on the way. Niron Magnetics is working to build iron nitride magnets, which produce a powerful magnetic field without the need for any rare earth metals. The company opened its first manufacturing facility in early 2024, and while its products can’t sub in for high-quality neo magnets just yet, there’s no fundamental reason they won’t be able to in the future. If Niron or other companies are able to develop new magnets, it could mean a shift in the rare earth market that quickly makes the current magnet recycling systems irrelevant.

In a perfectly sustainable world, we would use and reuse materials dug out of the ground indefinitely. But as our technology shifts and our lives change, it can be difficult to end the loop where it began. Instead, our material economy may morph into the shape of a spiral. Resources may not end up quite where they started— rather, the system we’ve set up to extract and use them will continue to chase technological progress, maybe endlessly.