Can the most exciting new solar material live up to its hype?

Testing perovskite solar cells in the lab used to require a decent pair of running shoes. The materials fell apart so quickly that scientists would bolt from where they made the cells to where they tested them, trying to measure their performance before the cells degraded in their hands—usually within a couple of minutes.

Perovskites have long enchanted researchers with the promise of producing inexpensive, ultra-efficient solar cells. And now several companies are making major strides toward producing commercial perovskite solar cells at scale.

But the materials’ instability has threatened to derail their path to rooftops and power plants. Though a few companies say they’ve solved the challenge, at least well enough to bring preliminary products to market within the year, some researchers are still skeptical.

“People want me to say ‘I know for sure this is going to be stable, and it’s going to be efficient and we’re going to conquer the world,’” says Joseph Berry, who leads the perovskite research program at the US National Renewable Energy Laboratory. “And part of me believes that, but part of me as a scientist says, ‘I don’t have the data.’”

Soaking up the sun

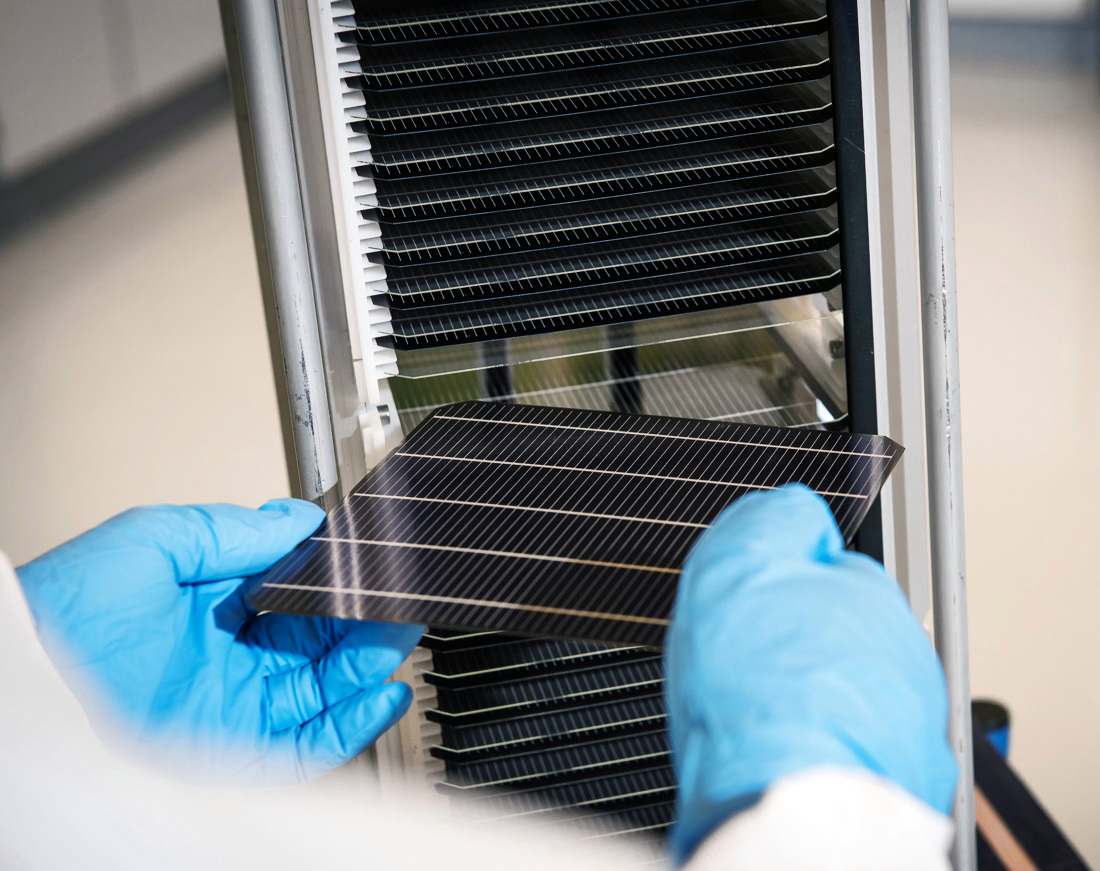

Perovskites are synthetic materials, inexpensive and relatively simple to produce even in large quantities. Common perovskites used in photovoltaics are typically something like methylammonium lead halide, but the perovskite family includes thousands of materials that share the same crystal structure. Coated onto a flexible base, they can produce thin-film solar cells that are light and bendable.

While several new photovoltaic materials have emerged in recent decades, none has made much of a dent in the market, which is dominated by silicon. It is found in around 95% of existing solar cells.

Some perovskite companies, like Saule Technologies in Warsaw, are trying to leave silicon behind altogether. The company, founded in 2014, developed an ink-jet printing process for manufacturing perovskite solar cells encased in a flexible plastic. A panel containing Saule’s cells is about a tenth as heavy as a silicon panel of the same size.

In May, Saule opened a factory that can produce around 40,000 square meters of panels annually. That’s enough to generate around 10 megawatts of power (some factories that produce silicon cells are hundreds of times larger).

While perovskites have the potential to reach high efficiencies (the world record for a perovskite-only cell is just over 25%), most of the best-performing perovskite cells today are tiny—less than an inch wide.

Scaling up makes it more difficult to reach the potential efficiency limits. Right now, Saule’s panels, which are a meter wide, reach around 10% efficiency. This is dwarfed by commercial silicon panels of similar sizes, which typically hit around 20% efficiency.

Olga Malinkiewicz, Saule’s founder and chief technology officer, says the company’s goal was to get a perovskite-only solar cell out the door, and the lower efficiencies won’t matter if the technology is cheap enough.

Saule is trying to go where silicon solar panels won’t: to roofs that can’t handle the weight of heavy glass-encased panels, or to more specialized applications, such as solar-powered blinds, which the company is currently testing.

While Saule is launching thin-film products for more niche applications, other companies hope to beat, or at least join, silicon at its own game. UK-based Oxford PV is incorporating perovskites into combination perovskite-silicon cells.

Since silicon absorbs light toward the red end of the visible spectrum, and perovskites can be tuned to absorb different wavelengths, coating a layer of perovskite on top of silicon cells allows combination cells to reach higher efficiencies than silicon alone.

Oxford PV’s combination cells are heavy and rigid, like silicon-only cells. But since they’re the same size and shape, the new cells can easily slot into panels for rooftop arrays or solar farms.

Chris Case, Oxford PV’s chief technology officer, says the company is focused on lowering the levelized cost of electricity, a metric that factors in a system’s installation and lifetime operation costs. While layering perovskites on top of silicon adds to the manufacturing cost, he says the levelized cost from the combination cell should dip below silicon over time because these new cells are more efficient. Oxford has set several world records in efficiencies for this type of cell in the last few years, most recently reaching 29.5%.

Microquanta Semiconductor, a Chinese perovskite company based in Hangzhou, is also taking some cues from silicon solar cells. The company is manufacturing panels from rigid, glass-encased cells that are made with perovskites.

Microquanta’s pilot factory opened in 2020, and should reach 100 megawatts of capacity by the end of the year, says Buyi Yan, the company’s chief technology officer. The company has demonstration panels installed on several buildings and solar farms throughout China.

Solving for stability

The stability of perovskites improved from minutes to months within the span of a few years. But most silicon cells installed today have a warranty of around 25 years, a target that perovskites may not yet be able to reach.

Perovskites are particularly sensitive to oxygen and moisture, which can interfere with the bonds in the crystal, stopping electrons from moving effectively through the material. Researchers have been working to improve the lifetime of perovskites, both by developing less reactive perovskite recipes and finding better ways to package them.

Oxford PV, Microquanta, and Saule all say they’ve solved the stability issue, at least well enough to sell their first products.

Estimating long-term performance in solar cells is usually done by accelerated testing, putting cells or panels under extra-stressful conditions to simulate years of wear and tear. The most common suite of tests for outdoor silicon cells is a series called the IEC 61215.

Oxford and Microquanta have both passed the tests in this series related to cell performance. Saule has passed some of the tests, but is still working on others, like the humidity test, Malinkiewicz says.

Passing the full series usually means a silicon solar panel will last at least 25 years, though researchers can’t be sure whether the same correlation holds true for new materials like perovskites.

Oxford PV screened some of the thousands of compounds that make up the perovskite family to find more stable formulations. The company declined to disclose performance details, although Case says they “absolutely” expect their products to have a similar lifetime to silicon cells. The company installed test panels on a roof in central Europe in December 2019, and Case says so far, the panels containing their perovskite-layered cells show the same degradation as commercial silicon panels they installed for comparison.

Yan at Microquanta says the company installed test cells outdoors in February 2020 that are still reaching the same peak power today as when they were installed.

To improve stability in its products, Saule made changes to the metal contacts in the cell, as well as to the perovskite layer. Saule’s first generation of plastic-encased perovskite cells will have a minimum 10-year performance warranty, Malinkiewicz says. While silicon cells last longer, she hopes the lower price and ease of installation will convince customers to accept a shorter lifetime.

Some researchers aren’t convinced by these claims. “The stability issues, as far as I know, have not been very well addressed,” says Letian Dou, a perovskite researcher at Purdue University in Indiana. Dou says it’s difficult to tell what these companies are up to since they keep their material developments secret, although he adds that passing external tests like the IEC 61215 is promising.

Dou’s lab is one of several that was recently selected to receive funding from the US Department of Energy to try to resolve some of the technology’s remaining issues. In March 2021, the department announced $40 million in grants to support research into perovskites, mostly for projects focused on improving the stability of these materials and making them easier to manufacture.

Even though perovskite cells are getting more funding and attention, only time will tell whether they can compete or coexist with silicon. Still, researchers are optimistic about the prospect of their delivering cheaper, more accessible solar power. “The signs are all good,” says Berry at the National Renewable Energy Laboratory.

And, he adds, even after years of research, companies working in this space will still have to accept some uncertainty. “If you want to be at the bleeding edge,” he says, “you’re going to have to live with some risk.”